Didirikan pada tahun 2007 dan pindah ke Longyou Economic Development Zone, Provinsi Zhejiang, pada tahun 2022. Ini mencakup area seluas 130.000 meter persegi, lebih dari 30 lini produksi, 300 pekerja, 20 orang R&D, 30 orang inspeksi dan output tahunan 50.000 ton.

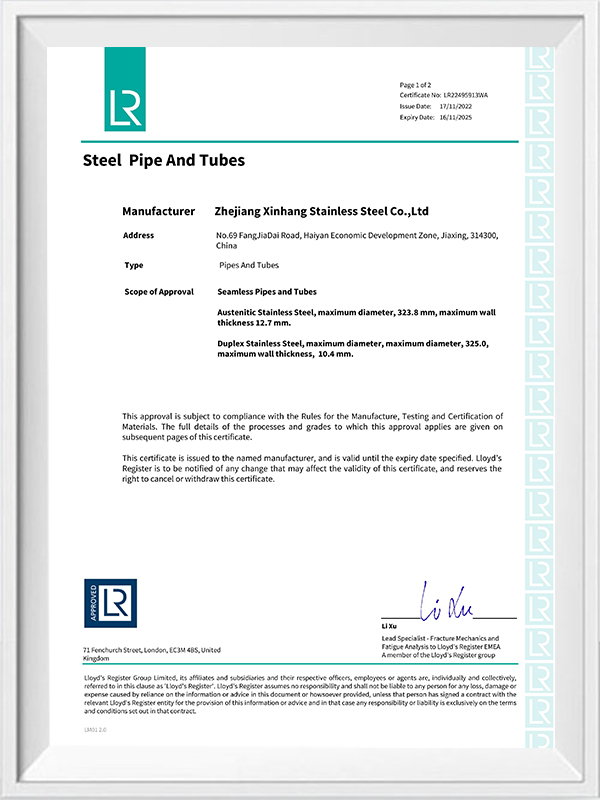

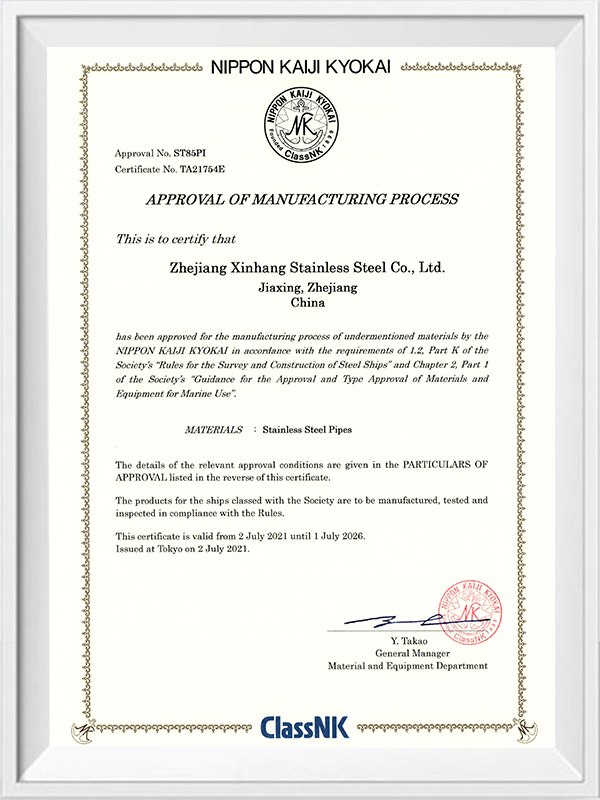

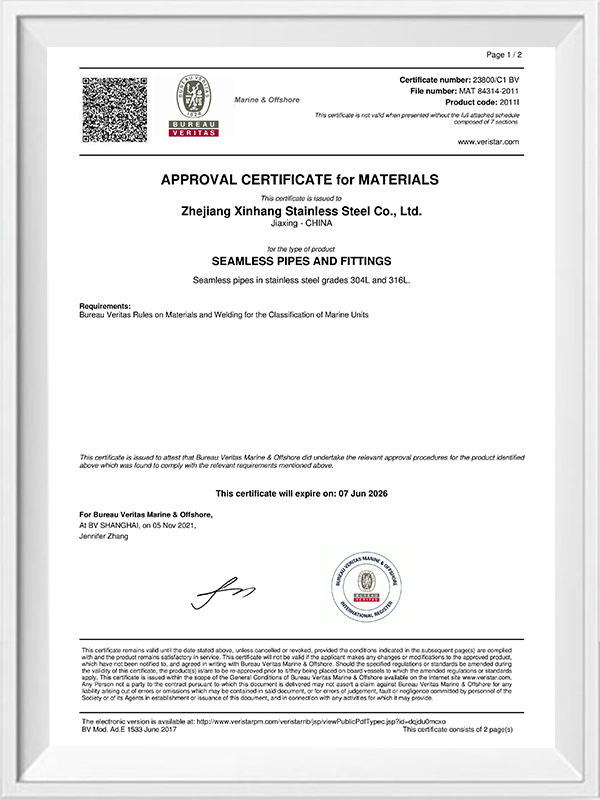

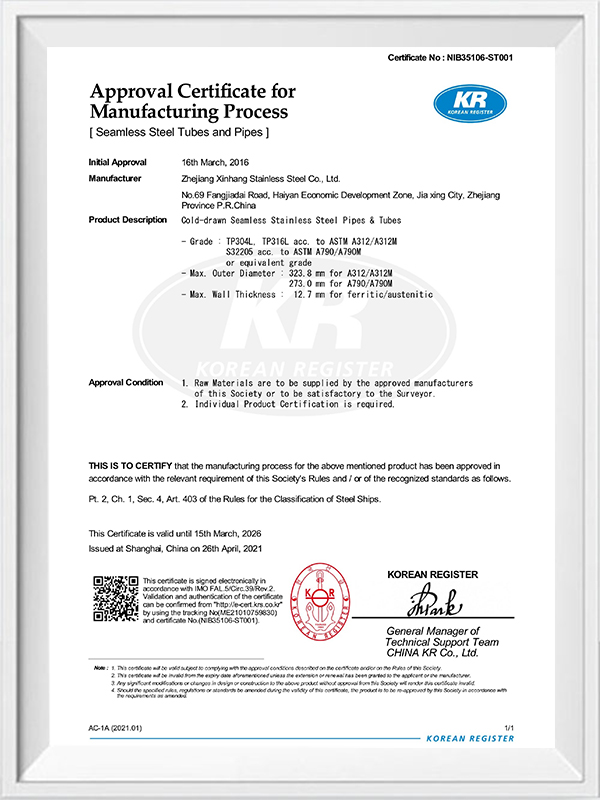

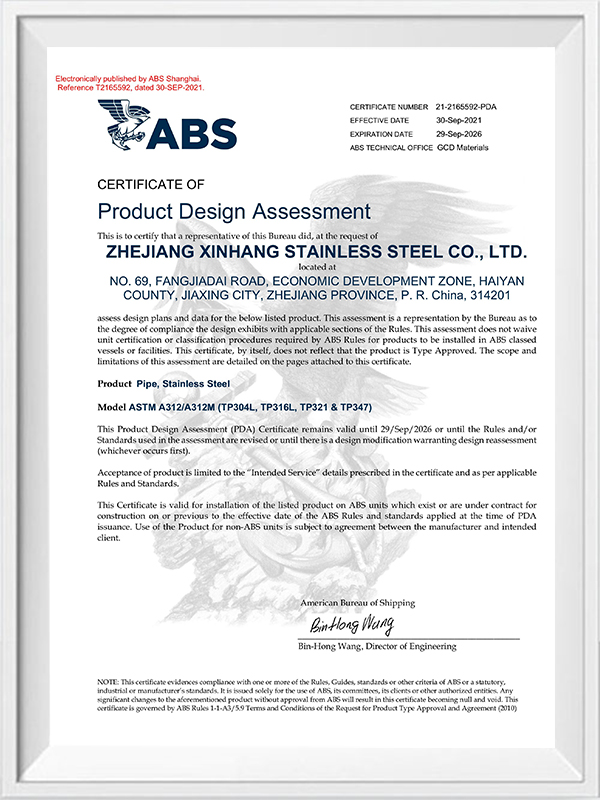

Telah lulus ISO9001: 2008 Sistem Manajemen Kualitas, PED 97/23/EC EU PRESSECH PRESSECH PEKERJAAN, LIEN LISE PRSEAL PRESIFIKASI KHUSUS KHUSUS (TUBA TEST) TS, Sertifikasi ASME, Sistem Manajemen Lingkungan, dan Sistem Lapangan Perusahaan (Cleafcy Enterprise), dan serangkaian serangkaian pelepasan, dan serangkaian serangkaian serangkaian pelepasan, juga serangkaian serangkaian serangkaian serangkaian, juga serangkaian serangkaian serangkaian serangkaian Lingkungan, juga serangkaian sertifikat, juga serangkaian sertifikat, juga serangkaian sertifikat, juga serangkaian serangkaian sertifikat, juga serangkaian sertifikat, juga serangkaian serangkaian serangkaian sertifikat, (LR), Deutsche Veritas (GL), Bureau Veritas Society (BV), Det Norske Veritas (DNV), dan Sertifikasi Pabrik Daftar Pengiriman Korea (KR).

Produk utama termasuk pipa stainless steel, alat kelengkapan pipa, flensa, katup, dll., Yang banyak digunakan dalam minyak bumi, industri kimia, industri nuklir, peleburan, pembuatan kapal, obat -obatan, makanan, konservasi air, tenaga listrik, energi baru, peralatan mekanis, dan medan lainnya. Perusahaan mematuhi prinsip perusahaan "Kualitas untuk Bertahan Hidup, Reputasi untuk Pembangunan" dan dengan sepenuh hati melayani setiap pelanggan untuk menciptakan situasi yang saling menguntungkan.

Pilihan alat pembakaran terbaik untuk pipa baja tahan karat Gunakan alat pembakaran presisi 37° (AN/JIC)...

Lihat lebih banyakIntinya: cara mengelas pipa stainless steel tanpa gula dan bocor Untuk sebagian besar pekerjaan pipa baja ta...

Lihat lebih banyakJawaban langsung: apa arti sebenarnya dari “peringkat tekanan pipa baja tahan karat”. Pipa baja tahan karat ...

Lihat lebih banyakApa yang ditentukan oleh pipa baja tahan karat SCH 10 (dan apa yang tidak) Dalam spesifikasi perpipaan, “SCH...

Lihat lebih banyakWhat industries commonly use sanitary stainless steel seamless tubes?

Food and Beverage Industry: Sanitary stainless steel seamless tubes are widely used in food processing, dairy production, breweries, wineries, and beverage manufacturing. They are crucial for maintaining hygiene and preventing contamination in food and beverage processing equipment, such as pipelines, tanks, and processing vessels.

Pharmaceutical Industry: In pharmaceutical manufacturing, where sterility is paramount, sanitary stainless steel seamless tubes are employed for transporting pharmaceutical ingredients, intermediates, and final products. They are used in the production of pharmaceuticals, vaccines, biologics, and other medical products to ensure purity and prevent cross-contamination.

Biotechnology and Life Sciences: Industries such as biotechnology, bioengineering, and life sciences rely on sanitary stainless steel seamless tubes for their critical processes, including fermentation, cell culture, purification, and sterilization. These tubes are integral to maintaining sterile conditions and preventing microbial contamination in bioprocessing equipment and systems.

Cosmetics and Personal Care: Manufacturers in the cosmetics and personal care industry utilize sanitary stainless steel seamless tubes for producing creams, lotions, shampoos, and other personal care products. These tubes help ensure product purity, hygiene, and safety by preventing bacterial growth and contamination during production and packaging processes.

Chemical Processing: Sanitary stainless steel seamless tubes are employed in chemical processing industries for handling corrosive chemicals, acids, and solvents. They offer resistance to chemical corrosion and maintain product integrity, making them suitable for applications such as chemical reactors, storage tanks, and piping systems.

Water Treatment and Purification: In water treatment and purification plants, sanitary stainless steel seamless tubes are used for conveying potable water, purified water, and wastewater. These tubes meet stringent sanitation standards and are resistant to corrosion, making them ideal for applications in water distribution systems, filtration units, and treatment processes.

Semiconductor and Electronics: The semiconductor and electronics industries utilize sanitary stainless steel seamless tubes in ultrapure water systems and cleanroom environments. These tubes ensure the delivery of high-purity water and chemicals to semiconductor fabrication processes, helping maintain the cleanliness and integrity of electronic components and microelectronics manufacturing.

Hospitality and Institutional Facilities: Sanitary stainless steel seamless tubes are also used in hospitality and institutional settings, such as commercial kitchens, restaurants, hospitals, and laboratories, where hygiene and sanitation are crucial. They are employed in food service equipment, medical devices, laboratory instruments, and plumbing systems to meet strict sanitary requirements and regulatory standards.

Are sanitary stainless steel seamless pipes compatible with other equipment and fittings?

Tri-Clamp Fittings: Sanitary stainless steel seamless pipes often feature tri-clamp (also known as tri-clover) fittings, which are widely used in industries such as food and beverage, pharmaceuticals, and biotechnology. These fittings provide a secure and hygienic connection between tubes, valves, pumps, and other components, ensuring easy assembly and disassembly for cleaning and maintenance.

Butt Weld Fittings: Seamless tubes can also be welded to other components using butt weld fittings. These fittings offer a permanent, leak-proof connection suitable for high-pressure and high-temperature applications. Butt weld fittings are commonly used in industries like chemical processing, oil and gas, and water treatment.

Threaded Fittings: In certain applications, sanitary stainless steel seamless tubes may be compatible with threaded fittings, allowing for easy installation and disassembly. Threaded connections are commonly used in plumbing systems, instrumentation, and low-pressure applications where sanitation is still important.

Flanged Connections: For applications requiring larger diameters or where frequent disassembly is necessary, flanged connections can be used with seamless tubes. Flanges provide a robust, bolted connection suitable for high-pressure and high-temperature applications in industries such as chemical processing, water treatment, and power generation.

Valves and Instrumentation: Sanitary stainless steel seamless tubes are compatible with a wide range of valves, instrumentation, and control devices commonly used in process industries. These include sanitary ball valves, diaphragm valves, butterfly valves, flow meters, pressure gauges, and temperature sensors, among others.

Piping Systems: Seamless tubes can be integrated into complex piping systems comprising various components such as pumps, heat exchangers, filters, and reactors. They are compatible with different piping materials, including stainless steel, PVC, polyethylene, and glass, allowing for versatile system designs to meet specific process requirements.

Sealing Materials: Depending on the application and process conditions, different sealing materials such as silicone, EPDM, Viton, or PTFE gaskets may be used to ensure a tight and hygienic seal between sanitary stainless steel seamless tubes and fittings. These sealing materials are selected based on their compatibility with the process fluid and sanitation requirements.

Kami tidak akan pernah membagikan alamat email Anda dan Anda

Dapat memilih keluar kapan saja, kami berjanji.